Product Description

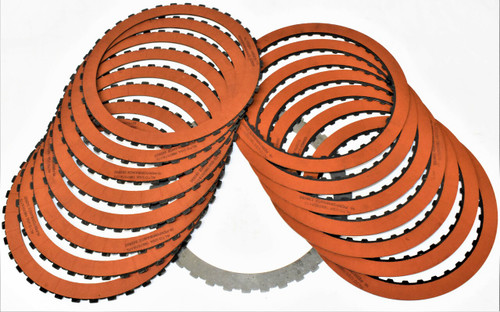

GM 6L80/6L90 High Performance 3-5-Reverse Clutch Powerpack w/ 2-Sided G3 Frictions

Made in theh USA by Alto Products Corp

IMPORTANT INFORMATION

The 195757B is designed to be a drop in, no machining required Hi-Performance kit for the 6L80/90E applications. Once installed, you may experience firmer shifts & Reverse engagements compared to a transmission equipped with stock OEM clutch plates. Prior to installation, pre-soak the friction plates for at least 20 minutes in the manufacturer’s recommended ATF or the ATF that the clutch plates will be used in.

Contents

- (7) 195702A170 (.067” / 1.70mm) G3® Frictions

- (6) 195703AK170 (.067” / 1.70mm) Kolene® Anti-Drag Steel Plates

- (1) 195703AK200 (.078” / 2.00mm) Kolene® Anti-Drag Steel Plate

- (1) 195763 (.191” / 4.85mm) Stepped Pressure Plate

- (1) 001227A Sub Kit, Anti-Drag Rubber Inserts

Directions

6L80E 3-5-R Clutch

Install the OE factory wave plate on top of the apply ring (stamping # 24633, 1.84” height), then install the .078”/2.00mm steel plate without any of the Anti-Drag Rubber Inserts. Then install an .067”/1.70mm G3 friction plate. Install (6) Anti-Drag Rubber Inserts into the notched teeth of (4) of the .067”/1.70mm Kolene steel plates. The Anti-Drag Rubber Inserts should be installed so that the longer end is facing the Inside Diameter of the Kolene steel plate (Illustration #1). Install one of the .067”/1.70mm Kolene steel plates with the Anti-Drag Rubber Inserts into the drum so that the Anti-Drag Rubber Inserts are aligned in between the notched teeth of the bottom steel plate (Illustration #2). Note: When installing the Kolene steel plates with the Anti-Drag Rubber Inserts, do so gently, forcing them into the drum may damage the Anti-Drag Rubber Inserts. Alternate G3 friction & Kolene steel plates with the Anti-Drag Rubber Inserts, making sure that the teeth with the Anti-Drag Rubber Inserts are staggered as you stack the drum (Illustration #3). Continue until the last plate installed is a friction plate (5 frictions & 5 steels). Install the Stepped top pressure plate included in this kit & the OEM snap ring. When installing the pressure plate, you will need to push it down some while installing the snap ring. Ensure that the opening of the snap ring is installed in the correct position. Once the snap ring is installed, ensure that all of the friction plates will rotate smoothly and have very little up & down movement. There are four selective thickness snap rings available for the 3-5-R clutch pack to help adjust clearance. When building a 6L80E drum, you will have extra plates left over.

Additional Option: For very high horsepower 6L80E applications, you can install one additional G3 friction & Kolene steel plate with the Anti-Drag Rubber Inserts (6 frictions & 6 steels) by removing the factory wave plate. This will most likely require a .076”/1.93mm or .087”/2.20mm selective snap ring that is not included in this kit. Removing the wave plate will create much firmer 2-3 and 4-5 shifts as well as firmer Reverse engagements.

6L90E 3-5-R Clutch

Install the OE factory wave plate on top of the apply ring (stamping # 26735, 2” height), then install the .078”/2.00mm steel plate without any of the Anti-Drag Rubber Inserts. Then install an .067”/1.70mm G3 friction plate. Install (6) Anti-Drag Rubber Inserts into the notched teeth of (5) of the .067”/1.70mm Kolene steel plates. The Anti-Drag Rubber Inserts should be installed so that the longer end is facing the Inside Diameter of the Kolene steel plate (Illustration #1). Install one of the .067”/1.70mm Kolene steel plates with the Anti-Drag Rubber Inserts into the drum so that the Anti-Drag Rubber Inserts are aligned in between the notched teeth of the bottom steel plate (Illustration #2). Note: When installing the Kolene steel plates with the Anti-Drag Rubber Inserts, do so gently, forcing them into the drum may damage the Anti-Drag Rubber Inserts. Alternate G3 friction & Kolene steel plates with the Anti-Drag Rubber Inserts, making sure that the teeth with the Anti-Drag Rubber Inserts are staggered as you stack the drum (Illustration #3). Continue until the last plate installed is a friction plate (6 frictions & 6 steels). Install the Stepped top pressure plate included in this kit & the OEM snap ring. When installing the pressure plate, you will need to push it down some while installing the snap ring. Ensure that the opening of the snap ring is installed in the correct position. Once the snap ring is installed, ensure that all of the friction plates will rotate smoothly and have very little up & down movement. There are four selective thickness snap rings available for the 3-5-R clutch pack to help adjust clearance. If you opt to use the OE wave plate, you will have an extra friction & steel left over.

Additional Option: For very high horsepower 6L90E applications, you can install one additional G3 friction & Kolene steel plate with the Anti-Drag Rubber Inserts (7 frictions & 7 steels) by removing the factory wave plate. This will most likely require a .076”/1.93mm or .087”/2.20mm selective snap ring that is not included in this kit. Removing the wave plate will create much firmer 2-3 and 4-5 shifts as well as firmer Reverse engagements. Note: It is very important that the correct apply ring is utilized. A 6L80E apply ring (stamping # 24633, 1.84” height) should not be used in a 6L90E drum or premature 3-5-R clutch failure will occur.

ALTO PRODUCTS CORP # 195757B